Freewheel Clutches - Stieber

STIEBER

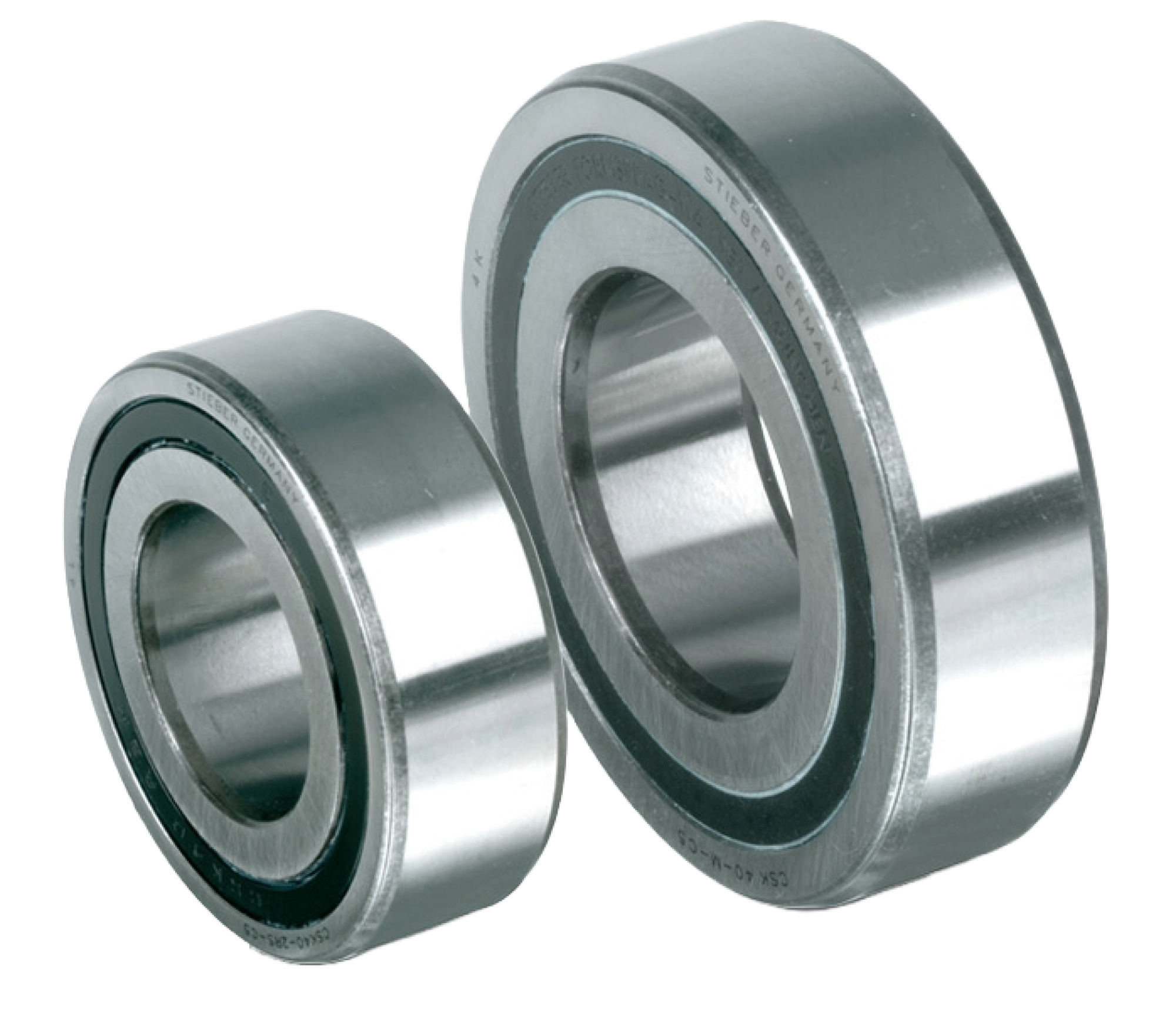

CSK-2RS

Type CSK is a sprag type freewheel integrated into a 62 series ball bearing (except sizes 8 and 40). It is bearing supported, delivered grease lubricated and protected against dust of more than 0,3 mm. The use of additional “nylos” type seals is recommended especially when the working temperature exceeds 50°C. Oil bath lubrication is also possible.

All the CSK versions are equipped with “formchromed” sprags. This process increases several times the overrunning life time. Torque transmission is ensured by a press fit assembly into a rigid steel housing with N6 tolerance, and onto a shaft with n6 tolerance. For this reason, the initial bearing radial clearance is set at C5.

Please contact us when either the ambient or the operating temperature is not within the range +5°C to +60°C.

CSK..2RS is 5 mm wider but is equipped with lip seals to be water splash resistant.

STIEBER

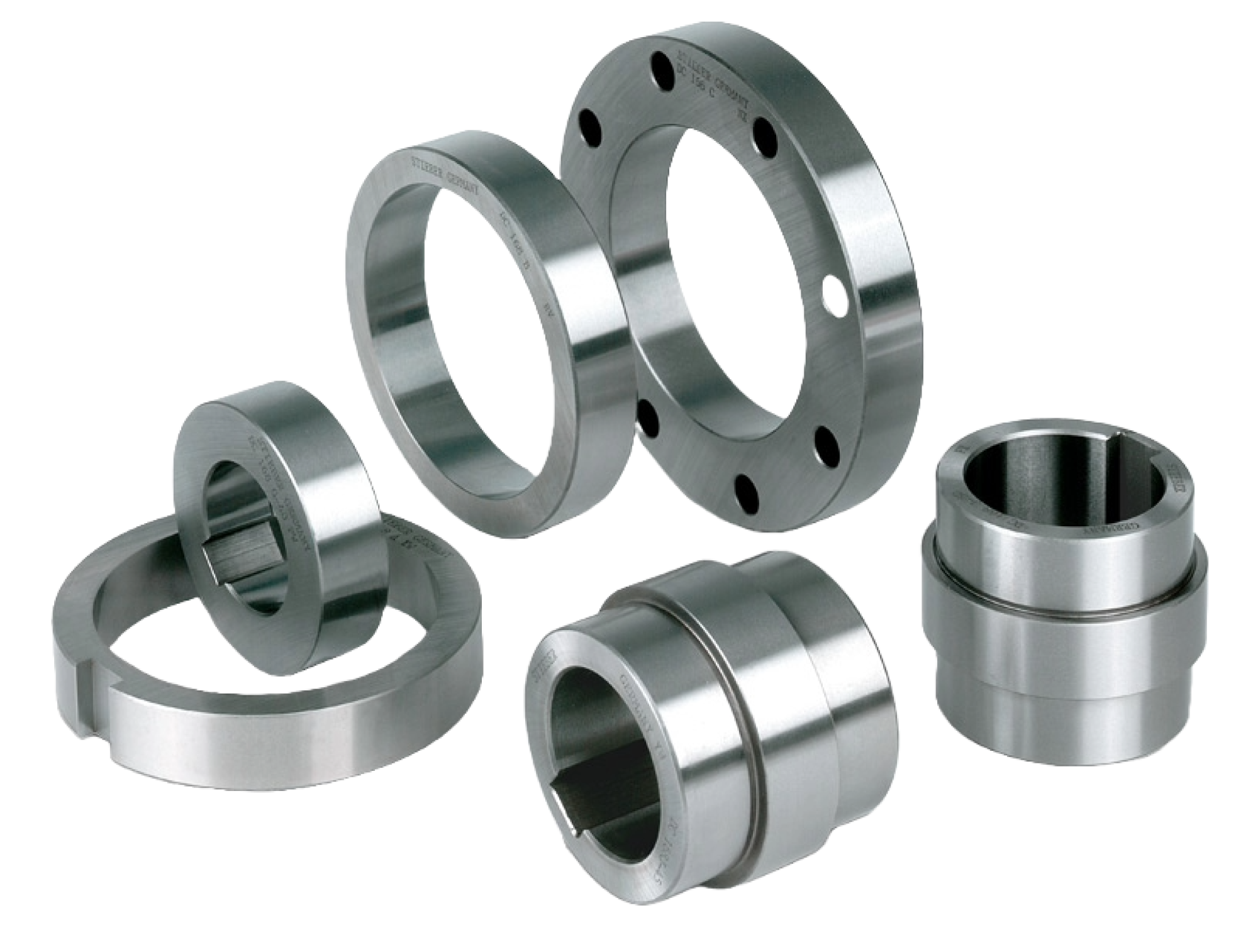

DC-RACES

DC races are offered for use with the DC freewheel cages shown on the previous pages. The cage and race assembly, makes a non-bearing supported freewheel.

Bearing support for axial and radial loads must be provided, along with lubrication and sealing. The sprag space tolerance must not be exceeded when all bearing clearances and mounting tolerances are considered.

Taper between races should be below 0,007 mm for 25 mm width. Outer races type A* and B* should be pressed into housings that will not deform after assembly. Please contact our technical department if you need to transmit maximum freewheel torque capacity with A* and G* type. Key stresses may have to be checked.

*) - These data refer to the indications in the product data sheet attached below (on page 2).

STIEBER

AL ALP

Types AL, ALP are roller type freewheels. These units are part of the Stieber modular system. They are bearing supported, using two 160.. series bearings, and require oil lubrication. These units may be used in designs providing oil lubrication and sealing as on the example overleaf.

The bearings must not be axially stressed. Typically, types AL, ALP are used with standard covers that are designed to transmit torque, and provide oil lubrication and sealing. Usually these covers are used in pairs according to combinations shown on the following pages. The outer race of the AL model is plain to receive and center any component bored to H7* tolerance. Torque is transmitted by bolts through the cover plate in this case. Types AL, ALP are identical except that type ALP has a keyway on the outside diameter to transmit the torque. Two paper seals are delivered with each unit to be placed between the outer race and cover plates.

*) - These data refer to the indications in the product data sheet attached below (on page 2)

STIEBER

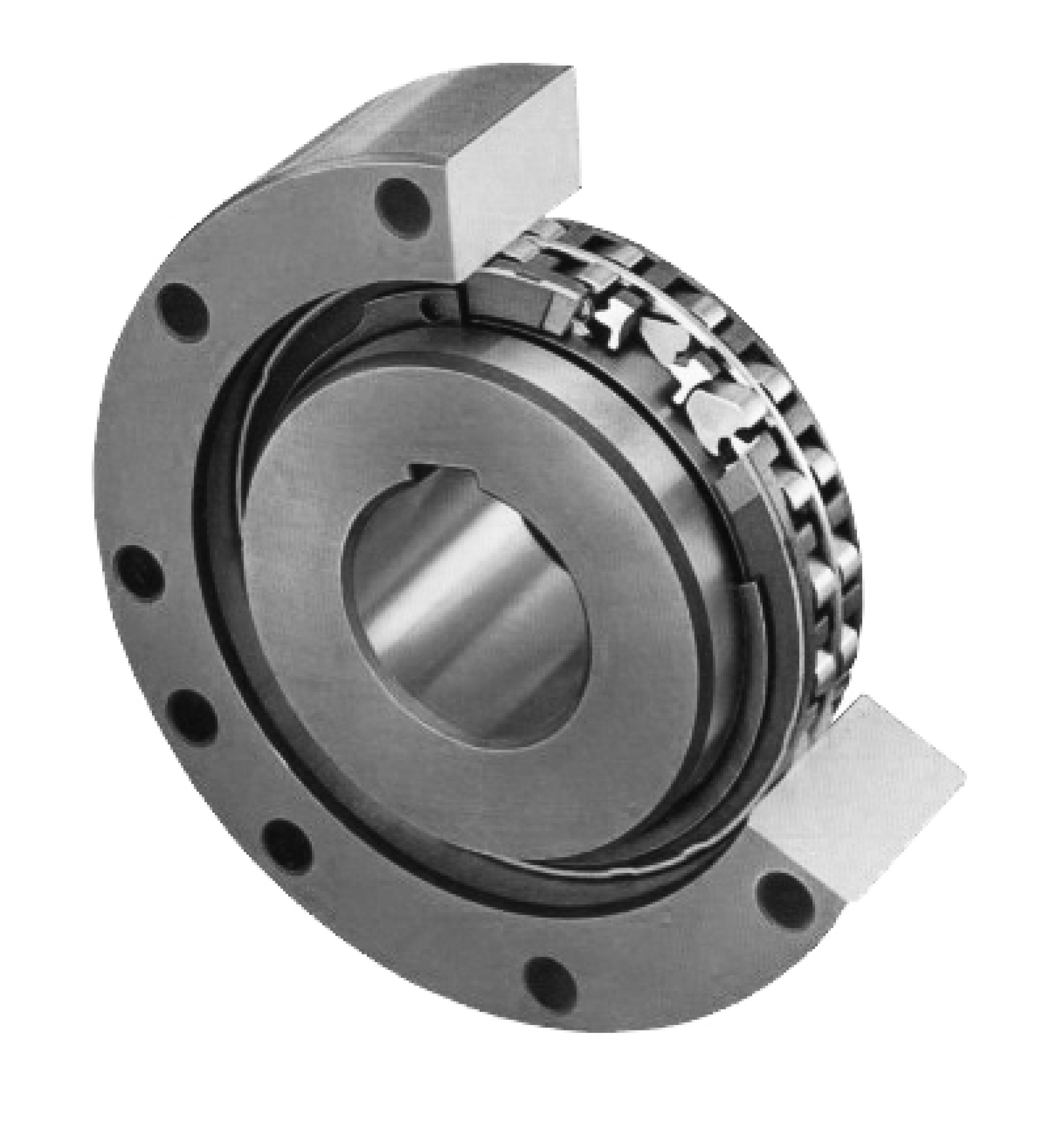

RSBW

Type RSBW is a DC sprag type freewheel. It is self-contained, centered by plain bearings for low rotational speeds and sealed using shield protected O Rings.

Unit is delivered grease lubricated ready for installation in either a horizontal or vertical position. Primarily used as a backstop, this type provides a high torque capacity with a minimum space requirement. The design allows installation in difficult environments such as high humidity or water splash areas.

A bolt, secured to a fixed part of the machine and passing through the slot in the torque arm, provides the rotational stop.

Radial clearance on this bolt should be equal to 1–3 % of the slot width. The torque arm and the bearings must not be pre-stressed.

STIEBER

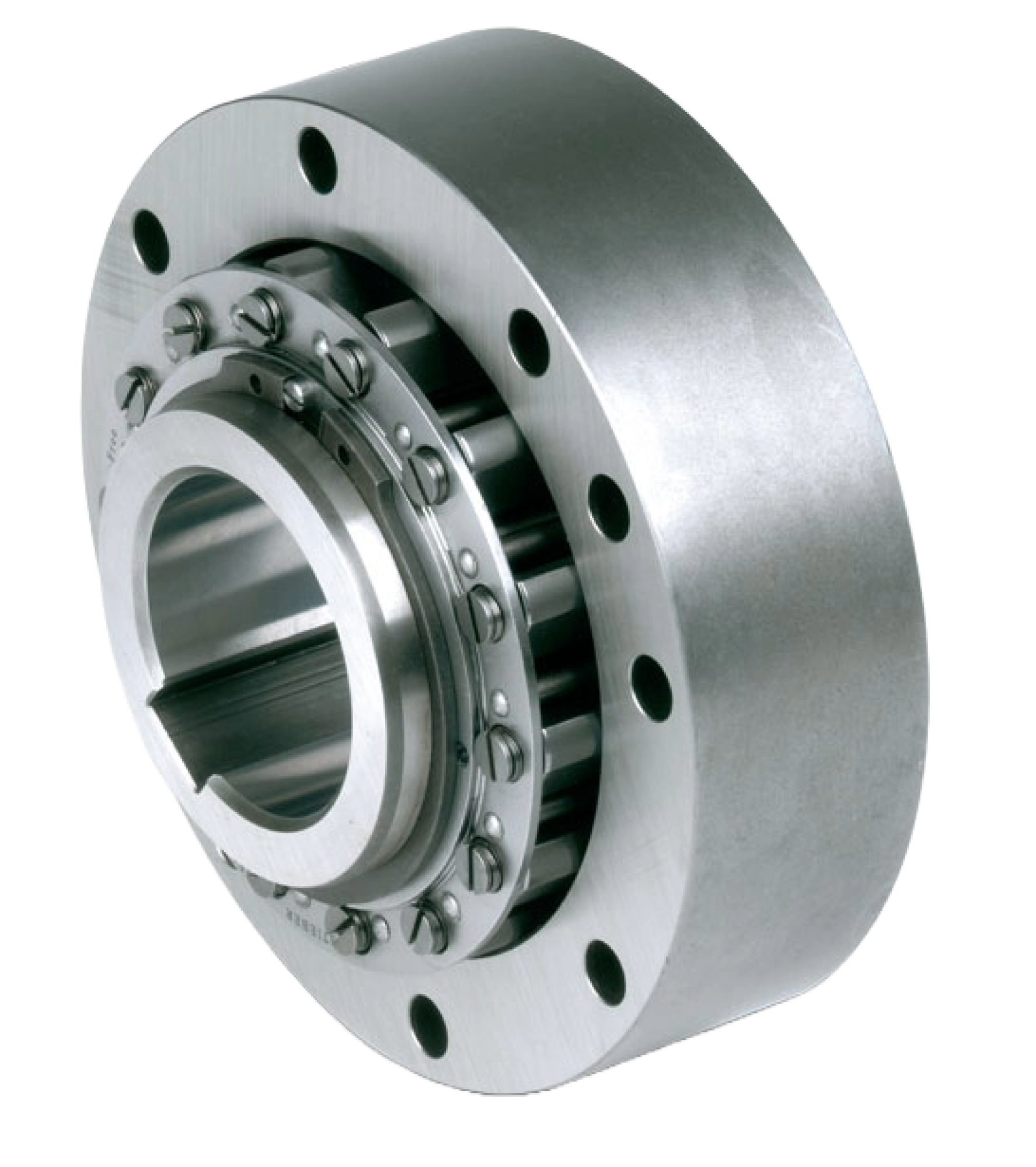

ASNU

Type ASNU is a roller type freewheel non-bearing supported. Bearings are required to support axial and radial loads. Lubrication and sealing must also be provided by the installation. Nominal outer diameter is the same as a series 63.. ball bearing.

A typical arrangement is to install this type alongside a bearing within the same location tolerances, as shown on the following page. The inner race is keyed to the shaft. The outer race has positive n6 tolerance, to give a press fit in a H7* housing. Additional side notches in the outer race provide for positive torque transmission.

If the housing is to K6* tolerance, use of the notches is not necessary, but the housing must be strong enough to not expand after assembly. This design can accept an axial misalignment of inner and outer race of ± S/2*.

*) - These data refer to the indications in the product data sheet attached below (on page 2).

STIEBER

RSCI 180-300FP

Type RSCI is a centrifugal lift off sprag type freewheel with the inner race rotating. Only the inner race is designed for freewheeling.

Primarily designed as a backstop, this type can be also used as an overrunning clutch in crawl drives, where the overrunning speed is high but the driving speed is low and does not exceed the maximum driving speed shown in the table. Centering of the outer race must use the inner bore. The centering spigot must not contact the sprag cage.

Please refer to RSCI 20-130 for further information.

*) - These data refer to the indications in the product data sheet attached below (on page 2).

STIEBER

GFR GFRN

Types GFR, GFRN are roller type freewheels. These units are part of the Stieber modular system. They are bearing supported, using two 160.. series bearings, and require oil lubrication. These units may be used in designs providing oil lubrication and sealing as on the example overleaf. The bearings must not be axially stressed.

Typically, types GFR and GFRN are used with the F series covers that are designed to transmit torque, and provide oil lubrication and sealing. Usually these covers are used in pairs according to combinations shown on the below technical data pages. The outer race of the GFR model is plain to receive and center any component bored to H7* tolerance.

Torque is transmitted by bolts through the cover plate in this case. Types GFR, GFRN are identical except that type GFRN has a keyway on the outside diameter to transmit the torque. Two paper seals are delivered with each unit to be placed between the outer race and cover plates.

*) - These data refer to the indications in the product data sheet attached below (on page 2).

STIEBER

RSCI 20-130FP

Type RSCI is a centrifugal lift off sprag type freewheel with the inner race rotating. Only the inner race is designed for freewheeling. It is a non self-supported type.

Bearings must be provided to ensure concentricity of the inner and outer races and support axial and radial loads, as shown overleaf. Concentricity and run-out limits must be observed. The RSCI type accepts all types of lubricant currently used in power transmission equipment. It is possible to mount these freewheels directly in gearboxes without separate lubrication. An oil mist is generally sufficient. Grease lubrication may be acceptable if the unit works mostly in overrunning condition, as on E-motors.

When used as a backstop, it must be checked that the overrunning speed will not go below the minimum speed given in the characteristics table. Please refer to page 74 (RSCI 180–300) for further information.

STIEBER

AS

Type AS is a roller type freewheel non bearing supported. Bearings are required to support axial and radial loads. Lubrication and sealing must also be provided by the installation. Nominal outside dimensions are the same as series 62.. ball bearings.

A typical arrangement is to install this type alongside a series 62 bearing within the same location tolerances.

The inner race is keyed to the shaft (except 6 mm bore). The outer race has a positive r6* tolerance to give a press fit in a H7* housing. The outer housing must be strong enough to not expand after assembly. This design can accept an axial misalignment of inner and outer race of ± S/2*.

*) - These data refer to the indications in the product data sheet attached below (on page 2).

STIEBER

DC

Type DC is a sprag type freewheel cage without inner or outer races. It must be installed in a design providing races, bearing support for axial and radial loads, lubrication and sealing. The DC type version-N accepts all types of lubricants currently used in the power transmission equipment.

The sprag space tolerance must not be exceeded. Inner and outer races must both have a minimum plain width “e*”, without any recess, to ensure the freewheel functions correctly as shown on following pages.

Alternatively, races can be made in case hardened steel shafts, or housings, to the specification below. Surface hardness of the finished part should be HRC 60 to 62, for a depth of 0,6 mm minimum. Core hardness to be HRC35 to 45. Surface roughness not to exceed 22CLA. Maximum taper between races: 0,007 mm for 25 mm width.

*) - These data refer to the indications in the product data sheet attached below (on page 2).